TSMC CEO reveals when it will ship 2nm chips to customers like Apple

The next generation of chipsets produced using the 3nm process node won't start being widely used inside smartphones and other mobile devices until next year. But when you are in the business of manufacturing complex chipsets with each containing billions of transistors, you have to start building fabs and other facilities years in advance. According to Tom'sHardware, the world's largest independent foundry, TSMC, recently gave an update on its plans to build 2nm components which it expects to start shipping to customers in 2026.

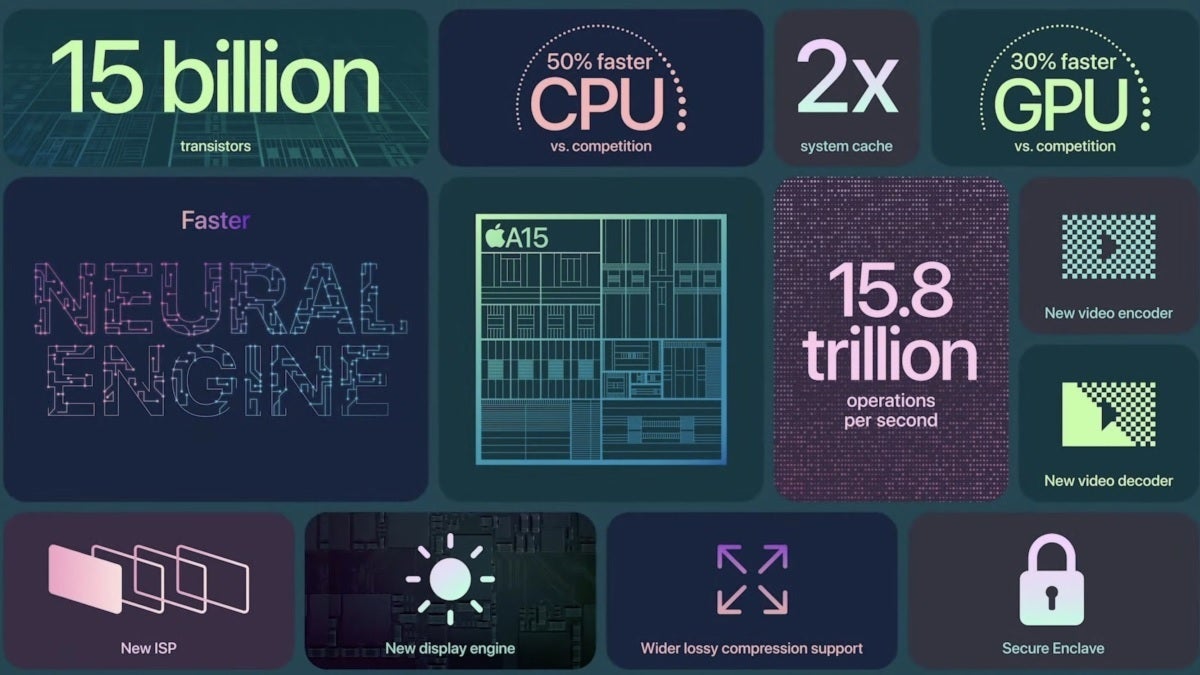

Typically, the smaller the process node, the larger the number of transistors that fit inside a chip. And as the number of transistors inside chips grows (the A15 Bionic has 15 billion transistors inside compared to the 11.8 billion transistors placed inside the A14 Bionic), chips become more powerful and energy-efficient.

TSMC expects to ship 2nm chips to customers by 2026

This week, TSMC CEO C.C. Wei discussed the foundry's plans for its 2nm process node known as N2. Wei did confirm that the transistors that TSMC will use with its 2nm components will be gate-all-around (GAA); the company will continue to rely on ASML's Extreme Ultraviolet Lithography to mark up wafers with the circuitry patterns needed to fit those billions of transistors inside each chip die.

TSMC builds the A15 Bionic chip used by Apple on the iPhone 13 series

The foundry's top executive added that "Our N2 development is on track, including new transistor structure and progressing to our expectation. All I want to say is that yes, it is [in] the end of 2024 you will enter the risk production. In 2025 it will be in production, probably close to the second half, or you know in the end of 2025. That's our schedule."

TSMC's customers, which include Apple, will start receiving 2nm chips in 2026. While TSMC will use GAA transistors for its 2nm mode, it will continue using FinFET for 3nm production while Samsung will be using GAA for its 3nm chips. Thus, Samsung Foundry will have a head start using GAA by the time TSMC starts using it for 2nm.

Despite that two-three year lead for Samsung Foundry, TSMC's Wei says that its first-generation GAA will be the best technology available. "We expect our N2 […] to be the best technology, [delivering] maturity, performance, and cost for our customers," said Wei. "We are confident that N2 will continue our technology leadership to support our customer growth."

Compared to Samsung and Intel, TSMC is working at a more deliberate pace for its 3nm and 2nm production. As we said, Samsung is already looking to use GAA for its 3nm process node on chips being shipped to customers next year. Intel plans on using a form of GAA transistor called Ribbon FET in combination with ASML's new cutting-edge lithography machine.

Samsung has the early lead in the use of Gate-all-around (GAA) transistor architecture

TSMC still believes that FinFET has a few more years left before it needs to change the architecture of its transistors. TSMC had been updating to a new process node every two years, but that now seems to be stretching out to every three years. It can get away with this by stretching out each node with enhancements, but its competitors appear to be more aggressive and that is typical as the leader in every industry has a target painted on its back.

Intel has been extremely aggressive in making forecasts. Back in October, Intel Chief Executive Officer Pat Gelsinger said that his company would regain process leadership in the industry, taking over from TSMC and Samsung by 2025.

Talking about Moore's Law, the observation made by Fairchild and Intel co-founder Gordon Moore that calls for the number of transistors in a chip to double every other year, Gelsinger said, "Moore's law is alive and well. Today we are predicting that we will maintain or even go faster than Moore's law for the next decade. We as the stewards of Moore's Law will be relentless in our path to innovate."

By 2026, we should know if Gelsinger's forecast came true.

Things that are NOT allowed: