TSMC completes the construction of its Phoenix-based fab which will produce 5nm chips in 2024

Coming on the heels of Congress' passing of the Chips and Science Act, a bill that will help the U.S. government subsidize chip production in the states, TSMC has announced that it has completed the construction of Fab 21. You might wonder what the connection is between a Taiwan-based foundry finishing off a new $12 billion fab and the U.S. The answer is that TSMC's Fab 21 is located in Phoenix, Arizona.

On LinkedIn, TSMC announced "We recently celebrated placing the last beam – also known in the construction industry as a 'topping' milestone - in FAB 21’s fab building with our local partners. Over 4,000 attendees were on hand to enjoy this important moment including our own employees and partners. #TSMCArizona is on time and on track to bring the most advanced leading-edge semiconductor technology to the U.S. We are deeply grateful to our partners and look forward to more successful milestones in Arizona."

TSMC hopes to start production of 5nm chips in Arizona starting in 2024

After taking only 16 months to construct the building, the next step is to bring in the equipment. The World's leading independent foundry hopes to start the production of 5nm chips inside the states by 2024. By the time that these components start shipping, TSMC's Taiwan fabs will be manufacturing 3nm chips with 2nm expected by 2026. The lower this process node number, the higher the transistor count for these chips. The higher the transistor count, the more powerful and energy-efficient these chips are.

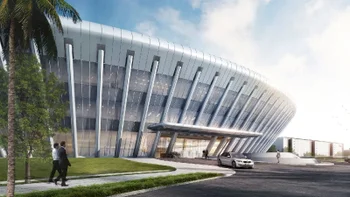

TSMC celebrates the completion of the structure known as Fab 21 in Phoenix, Arizona

In other words, Fab 21 will be two process nodes behind the most cutting-edge process nodes by the time the Arizona facility starts the production of chips. That isn't terrible since many chips used in the auto industry are made using much older and mature technology and the 5nm process node is just now coming into its own for automobile manufacturing.

TSMC will start shipping 3nm chips later this year. Samsung has already started delivering 3nm chips to cryptocurrency minors using the gate-all-around transistor design that TSMC won't employ until it starts shipping 2nm product (expected by 2026).

TSMC's Arizona facility could be hampered by a culture clash between Taiwan and U.S. employees

Already there has been a clash of cultures as the management style used in Taiwan isn't playing well with U.S. employees. An anonymous U.S. employee working at the Arizona site complained last year about long meetings. This employee wrote in a Taiwan publication that the meetings that he characterized as "excessive" were running as long as three hours a day. Just before construction started on the facility in Phoenix, TSMC sent more than 100 Americans it hired to Taiwan partially to be indoctrinated in the way that things are done in the territory.

The Chips and Science Act will result in the U.S. government subsidizing the U.S. semiconductor industry to the tune of $52 billion to help produce more chips in the U.S. The goal is to make the U.S. self-sufficient in the semiconductor industry so that stateside tech firms like Apple don't have to hold their breath every time China looks crosseyed at Taiwan. There is always the fear that China, with its own desire to be self-sufficient in semiconductors, will try to take Taiwan and keep TSMC as its own.

As an independent foundry, TSMC takes designs created by its customers which include Apple (its largest client), Qualcomm (which also uses Samsung Foundry), rising star Mediatek, Nvidia, Intel, AMD, and others, and builds the finished component. Valued at $459 billion as of Friday's New York Stock Exchange close, TSMC is the 10th most valuable company in the world based on market capitalization (share price multiplied by the number of shares outstanding).

Things that are NOT allowed: