Apple supplier to start producing more powerful chips for future 5G phones

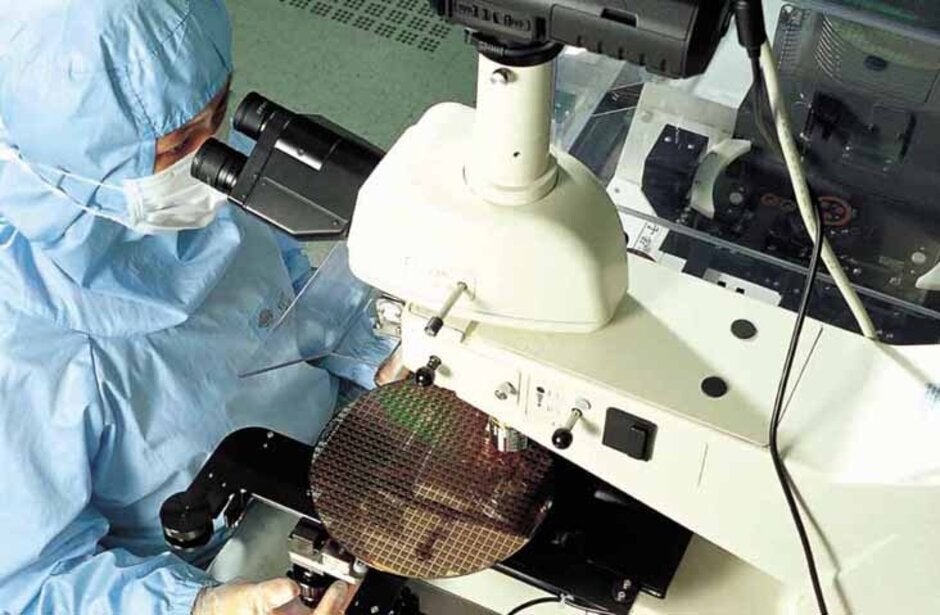

Something exciting is expected to take place starting next month. The largest independent chip foundry in the world, Taiwan Semiconductor Manufacturing Company (TSMC) is expected to kickoff production of integrated circuits made using its 5nm process. The lower the process number, the larger the number of transistors that fit inside a chip which increases the performance and decreases the energy consumption of these components.

TSMC takes designs created by other firms and does the actual manufacturing of a chip. Its customers include some of the biggest names in technology such as Apple, Huawei, Qualcomm, and MediaTek. For example, TSMC produces the A13 Bionic SoC used inside Apple's 2019 iPhone models. This chip, made using the 7nm node, contains 8.5 billion transistors. The A14 Bionic, which will be powering the 2020 5G iPhone line, will be manufactured using the 5nm process and each chip is expected to contain 15 billion transistors. The chip density for 5nm chips (the number of transistors per square mm) will rise 84% to 171.3 million. Believe it or not, that is actually less than the 100% density hike called for by Moore's Law, an observation made by Intel co-founder Gordon Moore back in the 1960s. The "Law" calls for this figure to double every other year.

TSMC, Samsung have roadmaps for 3nm chips as soon as 2022

In addition to Apple, Huawei's next Kirin chipset (known for now as the Kirin 1020) will roll off of the 5nm assembly line later this year, just in time to power the outfit's most technologically advanced phone series of 2020, the Mate 40 line. Unless Qualcomm radically redesigns its 2020 flagship Snapdragon 865 Mobile Platform for the second half of the year, most Android users won't benefit from the latest advancement in chip production until 2021 when phones using the Snapdragon 875 Mobile Platform are released.

TSMC will start producing 5nm chips next month

It's no surprise that 5nm is the next big thing in tech, but not everyone, save for those in the industry or enthusiasts, know that it was coming. Digitimes is reporting that TMSC has already fully booked all of its 5nm production capacity for this year after the foundry spent $2.5 billion on the process node. Industry sources say that the production of 5nm ICs will start next month.

Earlier today, we told you that Samsung is the midst of putting together its own 5nm production lines. The second-largest foundry in the world after TSMC, Samsung expects to start churning out 5nm ICs by this summer. Both TSMC and Samsung have roadmaps taking them to 3nm production which could start rolling off of assembly lines as soon as 2022. During last year's Samsung Foundry Forum, the company said that 3nm chips could deliver performance increases of up to 35% while consuming 50% less power compared to the current 7nm chips in use today.

Digitimes notes that Qualcomm rival MediaTek says that it has increased its revenue for the first two months of the year by over 25% on an annual basis. The company generated $1.01 billion USD in gross thanks to shipments of its 5G Dimesnity chips. Once again citing the anonymous "industry sources," the report says that shipments of these ICs are stronger than expected especially in the face of the coronavirus.

That is not to say that the pandemic isn't affecting the wireless industry. Last month, TSMC reported its lowest monthly revenue figure since August 2019 as the company took in $3.1 billion USD for February. While that was up 53.4% year-over-year, the figure was down 9.9% from January. For the first two months of the year, TSMC has reported revenue totaling $6.5 billion USD, up 41.8% on an annual basis. This month, TSMC expects revenue to exceed $3.34 billion USD as it earlier forecast first-quarter gross of $10.2-$10.3 billion USD. That would be a very small decline from last year's fourth-quarter total.

Things that are NOT allowed: