Report says Apple, TSMC talk about moving 3nm chip production to U.S.

One of the good things that came out of the Trump administration has been a focus on U.S. semiconductor production. This led the world's top foundry, TSMC, to open a chip-making fabrication facility in Phoenix, Arizona that is scheduled to come online in 2024 with chips rolling off of the line manufactured using the foundry's 5nm process node.

Apple and TSMC discuss moving 3nm chip production to the U.S.

Simply put, the lower the process node, the smaller the transistors employed in the component allowing more of them to fit inside the chip. This is important because usually the higher the number of transistors shoehorned inside a chip, the more powerful and energy-efficient it is. This year, Samsung Foundry will be shipping 3nm chips and next year TSMC will deliver the 3nm A17 Bionic to Apple for the iPhone 15 Pro and iPhone 15 Ultra.

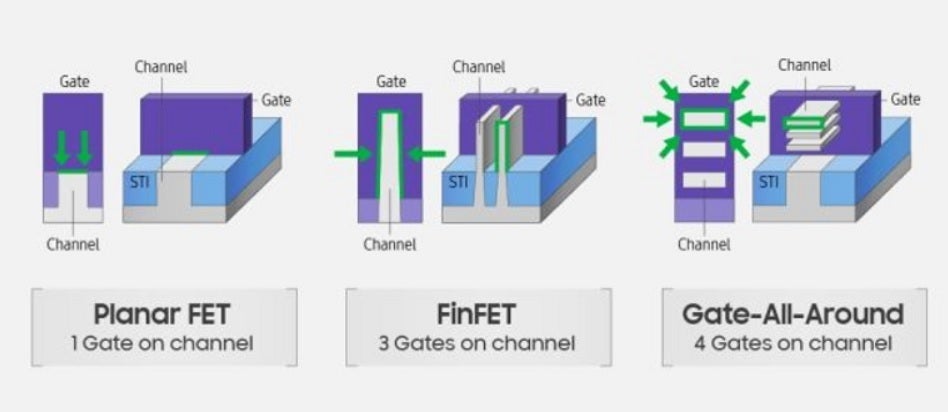

Gate All Around transistors will be used on Samsung's 3nm production and TSMC's 2nm production. Image Credit CopperPod

As an example, the A13 Bionic found in the iPhone 11 series from 2019 was made by TSMC using its 7nm process node and carries 8.5 billion transistors. The A16 Bionic used to power the iPhone 14 Pro models is made by TSMC using its enhanced 5nm process (which is called 4nm) and each chip is equipped with nearly 16 billion transistors. Back in May 2021, IBM announced that it had developed a 2nm chip that would be able "to fit 50 billion transistors in a space roughly the size of a fingernail."

Apple, which accounts for a leading 25% of TSMC's annual revenue, would love to move chip production to an area of the world that isn't as potentially a focus of China's attention as Taiwan is. With China looking to become self-sufficient in chip production, there is always the fear that the country has its sights set on Taiwan. Apple would love to move TSMC's cutting-edge production out of Taiwan and into the states.

As we said, TSMC's U.S. facility is expected to push out 5nm chips. But according to TechSpot, both Apple and TSMC are discussing moving TSMC's 3nm production to the states. This could require TSMC to bring in some more top talent to the U.S. Apple would be able to access its chips faster if TSMC could manufacture them in Arizona and perhaps this could relieve Apple of some of the concern it might have over the geopolitical situation.

Obviously this couldn't happen right away, and with the factory in Arizona not expected to open for business until 2025, by the time the 3nm process node is available to be made in the states, Apple could be looking at using a 2nm chip in the iPhone 17 Pro series. But if the company continues to differentiate the chips used int he non-Pro and Pro models, by 2025 the iPhone 17 and iPhone 17 Plus could be using chips made in the USA.

In addition, one of TSMC's factories is now working on a way to get the process node down to 1nm. Last month, Samsung Foundry announced a roadmap for its chip production which will go from this year's 3nm process node to 2nm in 2025. In 2027, Samsung Foundry says that it will be producing chips using a 1.4nm process node. Intel announced last year that new technologies will allow it to compete for process leadership by 2025 with TSMC and Samsung.

TSMC won't switch to Gate All Around transistors until it starts shipping 2nm chips

The problem that companies like TSMC, Samsung Foundry, and Intel face is how to make transistors smaller. The whole process is extremely complex. For the last few years, TSMC and Samsung Foundry have been using what is known as FinFET (fin-shaped Field Effect) transistors. Samsung this year started using Gate-All-Around (GAA) transistors.

The GAA transistors can have the gate come into contact with all four sides of the transistor's channel to give it more control over the flow of current (FinFET transistors only cover three sides of the channel) by replacing the vertical fin with horizontal stacks of what are called nanosheets. The GAA transistor, designed first by Samsung, can help reduce transistor size (the benefits of which we have previously mentioned) and improve transistor density allowing more transistors inside a chip.

The GAA chips also allow the channel to be widened inside the component which will allow the chip to be faster. It also will help drive more power-efficient chips. Keep in mind that TSMC is sticking to FinFET for its 3nm production and will use GAA when 2nm chips start rolling off the line. Samsung is already using GAA on its 3nm components.

Things that are NOT allowed: