TSMC's 3nm yield reportedly at 80% with Apple taking all of the chips it can get

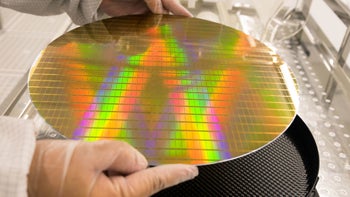

Where does the world's largest foundry, TSMC, stand now on the production of cutting-edge 3nm chips? According to EDN Asia, yields on the 3nm chip production it has been running off for Apple has been in the 80% area which means that out of every 100 chips created from a wafer, 80 pass quality control. High yields are important to TSMC's customers especially when wafers for 3nm chips cost $20,000 compared to the $16,000 that wafers for 5nm chips are priced at.

At the current price, chip designers outside of Apple have sat out the first generation of 3nm production. This process node is known as N3 inside TSMC and 100% of this production has been tied up by Apple. The iPhone 15 Pro and iPhone 15 Ultra will probably be the only smartphones to sport a 3nm SoC this year. But things are expected to pick up next year. That's because TSMC will start producing chips with its N3E process node during the second half of this year.

The 3nm node could generate $1.5 trillion in revenue for TSMC in the five years after starting volume production

Chips built with the N3E process node are cheaper and easier to build than those made using the N3 process. Taking advantage of the lower costs, TSMC expects other customers, like Intel, AMD, and Qualcomm to jump into the 3nm pool. It makes sense for those three companies to wait for the less expensive N3E because they are all chip designers selling chips. Their profits come from the chips themselves. Apple, on the other hand, is the end-user of its own chips and makes its money selling the expensive products it makes containing the silicon components it designs.

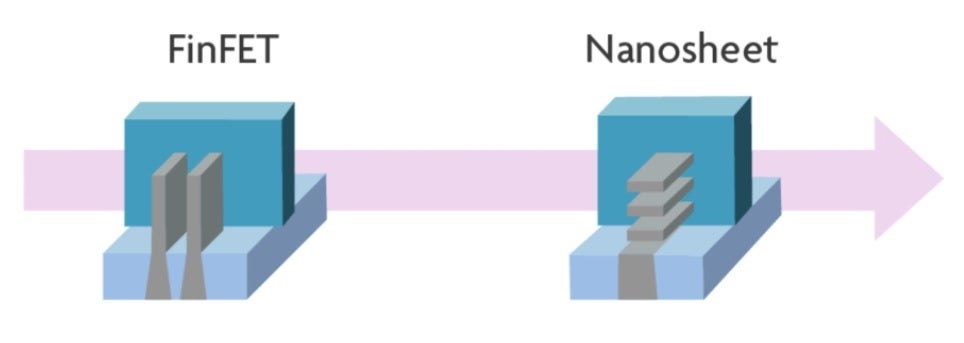

TSMC's 3nm chips still use FinFET transistors while Sammy's 3nm GAA chips feature Nanosheets for more current flow control

Chips made using N3E will have faster clock speeds and use less power than those made using the N3 node. The 3nm process is expected to generate $1.5 trillion for TSMC over the first five years after volume production according to CEO C.C. Wei.

TSMC says that the first 3nm node (N3) delivers 15% higher performance while consuming 30% to 35% less power compared to its 5nm node. The 4nm node, which is used on the Apple A16 Bionic, is actually an enhanced version of TSMC's 5nm node.

The 3nm Apple A17 Bionic is expected to provide a 35% power efficiency improvement over the A16 Bionic. Apple's M3, M3 Pro, and M3 Max chips are also expected to be manufactured using TSMC's 3nm node. Apple is the foundry's largest customer reportedly contributing 25% of TSMC's annual revenue.

TSMC, Samsung, and Intel will all be using GAA transistors at 2nm

Next year TSMC will reportedly start 4nm production at its new fab in Phoenix, Arizona. By 2026, a second fab will start churning out 3nm chips although by then, the talk will undoubtedly turn to 2nm which is when TSMC will switch from FinFET transistors to gate-all-around (GAA). The latter transistors allow the gate to come into contact with the channel on all sides using horizontal nanosheets stacked vertically. This allows current flows to be controlled more precisely while also reducing current leaks.

GAA chips also deliver greater power efficiency allowing devices using this technology to run faster while consuming less power. It should be pointed out that Samsung already uses GAA for its 3nm production while TSMC sticks with its FinFET transistors. Intel will also start using its version of GAA, which it calls RibbonFET, by the middle of 2024. The company says it will retake process leadership in 2025.

The EDN Asia reports cites Digitimes for reporting that TSMC hopes to have an output rate of 45,000 wafers monthly by this month. Even with Apple as the one and only customer for N3 production, TSMC will still take in billions of dollars in revenue for its N3 production this year. And the future will only look brighter for the foundry as the N3E node starts attracting more customers next year.

Things that are NOT allowed: