Next year's iPhone 14 could be the first smartphone to use TSMC's new packaging platform

According to Patently Apple, TSMC is working on a new packaging platform called 3DFabric. During the summer, the foundry's CEO, C.C. Wei, said, "We are working with several customers on 3DFabric to enable chiplet architecture." The world's largest independent foundry now says that its first customers employing the new 3DFabric technology will include Apple, AMD, MediaTek, Xilinx, NXP, and Qualcomm.

TSMC's new 3DFabric Packaging platform could debut on iPhone 14

With 3DFabric technology, TSMC's customers can use chiplets which are smaller chips that are used to create a larger Integrated Circuit. This technology can quicken the time-to-market for new technology since this platform allows customers to keep reusing parts of the component that do not change. And according to TSMC, "3DFabric allows the integration of high density interconnected chips into a packaged module delivering improved bandwidth, latency, and power efficiency."

TSMC will launch the 3DFabric Packaging platform once it starts shipping 3nm chips. TSMC was supposed to be manufacturing the Apple A16 Bionic chipset using the 3nm process node. But last month the company announced a delay due to the complexities of building a chip at this process node and the A16 Bionic will reportedly be made using the 4nm process node instead.

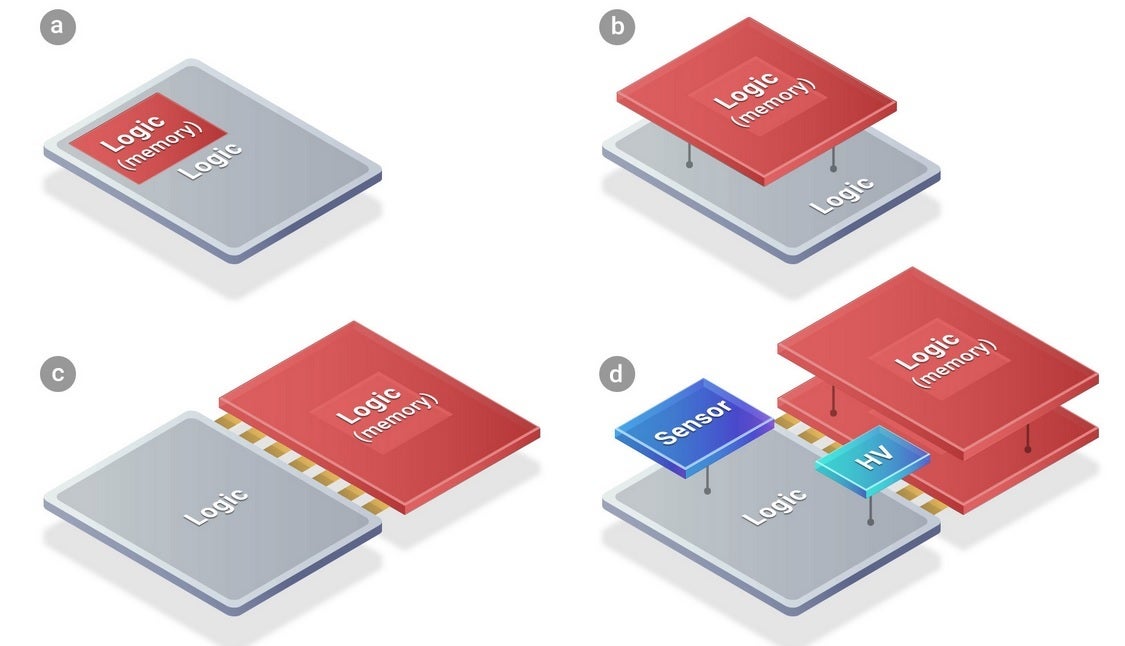

Diagrams show typical SoC (A) followed by SoICs using chiplets (B, C, D)

As a result, it isn't clear whether we will see the 3DFabric Packaging platform used in the iPhone 14 although Patently Apple's report says that "Apple's next-gen iPhones in 2022 are likely to use TSMC's 3D Fabric platform." The report goes on to add that with the platform, many AI functions, new memory types, and embedded chips will be combined. TSMC is expected to test the platform this year at its facilities in Zhunan and Nanke with mass production scheduled for the second half of 2022.

TSMC's new packaging platform takes a modular, Lego-like approach using chiplets

If this sounds like some kind of modular solution to packaging, it is. In a video that TSMC produced to show off the new platform, kids are playing with Lego blocks which is the ultimate modular toy. Liao Dedui, deputy general manager of TSMC’s advanced packaging technology and services, says that the 3DFabric brings together advanced packaging and testing technologies.

TSMC's blog discusses back-end technologies such as Chip-on-Wafer (CoW) and Wafer-on-Wafer (WoW) die stacking. These allow for the 3D stacking of both similar and dissimilar dies which can be used to provide more computing power by increasing the number of computer cores. It also provides more memory and higher bandwidth thanks to stacked memory, and will also improve power delivery.

This year, Apple is using the 5nm A15 Bionic in the just released iPhone 13 line. While 15 billion transistors are found in each A15 Bionic chip (up 27% from the 11.8 billion inside the A14 Bionic), the transistor density saw a much smaller improvement. This metric measures the number of transistors in a square mm and rose less than 1% from 134.09 million in the A14 Bionic to 135.14 million on the new chipset.

Apple apparently decided to spend money on improving graphics performance instead of the CPU. The company saw some of its best chip developers leave Apple which might account for the underwhelming CPU improvements year-over-year. While Apple usually likes to compare new components with the ones used on the previous year's models, this year comparisons were made "vs. the competition" and those firms (such as Samsung and Qualcomm) won't be shipping their next-gen chips until we get closer to the end of the year.

If TSMC is forced to ship a 4nm A16 Bionic instead of one made using the 3nm process node as originally planned, there will be some repercussions including smaller increases in performance and energy-consumption. Both TSMC and Samsung have road maps taking them to 2nm although there could be more bumps in the road as the foundries start dealing with even more4 complex and advanced processes.

Things that are NOT allowed: