Tipster makes weird claim about the performance of the iPhone 15 Pro's A17 Bionic in 2024

The Apple iPhone 15 Pro and iPhone 15 Pro Max are expected to be the only phones released this year that will be powered by a chip manufactured using the 3nm process node (the N3B process to be precise). That chip is the A17 Bionic which could have anywhere between 18 billion-20 billion transistors inside.

The iPhone 15 and the iPhone 15 Plus will use the hand-me-down A16 Bionic which is currently employed on the iPhone 14 Pro and iPhone 14 Pro Max. The A16 Bionic is made using TSMC's 4nm process node (essentially an enhanced 5nm node) and carries 16 billion transistors.

The reason why Apple is alone at 3nm has to do with the pricey wafers that these chips are built on. The silicon wafers for 3nm production cost about $20,000 for each slice. According to the Economic Daily News (via Wccftech), the world's largest foundry, and the company Apple uses to manufacture its chips, TSMC, will be producing chips on 90,000 to 100,000 wafers each month toward the end of the year. Most of this production will be for the A17 Bionic applications processor.

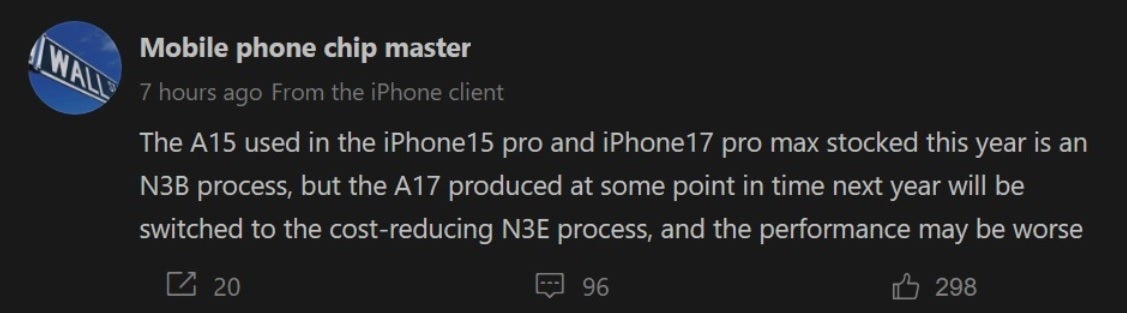

Supposedly, TSMC will switch at some point next year from using the N3B process to a lower-cost N3E process for the A17 Bionic. Normally, switching to a more advanced process node would deliver greater improvements in performance and energy efficiency. But according to a Weibo tipster using the handle "Mobile phone chip master," switching to the N3E process node will reduce the performance increases compared to the N3B process. That, of course, doesn't make any sense.

That's because when compared to TSMC's N5 (5nm) node, N3 consumes 30% less power and N3E consumes 32% less energy. Performance wise, the N3 node delivers a 15% improvement over N5 while N3E's performance hike is 18%. So it isn't clear where this drop in performance mentioned by "Mobile phone chip master" is coming from and as Wccftech points out, the tipster doesn't give any details about the performance and efficiency changes expected between N3B and N3E.

One reason why Apple is expected to raise its pricing on the iPhone 15 series this September, especially on the premium Pro models, is due to the high wafer costs that Apple will have to pay. Later this month, Foxconn is expected to start mass production of the iPhone 15 line with an initial goal of 85 million-90 million units. The contract manufacturer has already hiked its sign-up bonuses as it seeks to raise its headcount in time for the production of the latest iPhone models to start.

Foxconn will be the largest builder of iPhone 15 Pro and iPhone 15 Pro Max units with Luxshare as a secondary manufacturer. Interestingly, in a bid to diversify its supply chain, Apple is expected to use a different contract manufacturer for 2024's iPhone 16 Pro Max.

Follow us on Google News

Things that are NOT allowed:

To help keep our community safe and free from spam, we apply temporary limits to newly created accounts: