Top analyst sees demand for iPhone 14 Pro and iPhone 14 Pro Max disappearing

Just the other day Bloomberg released a report indicating that the COVID crackdown and resulting chaos in Zhengzhou, China would result in a shortage of 6 million iPhone 14 Pro and iPhone 14 Pro Max units. The Foxconn factory in the city saw an exodus of workers starting a few weeks ago when China imposed rules designed to prevent the resurgent COVID virus from spreading throughout the country.

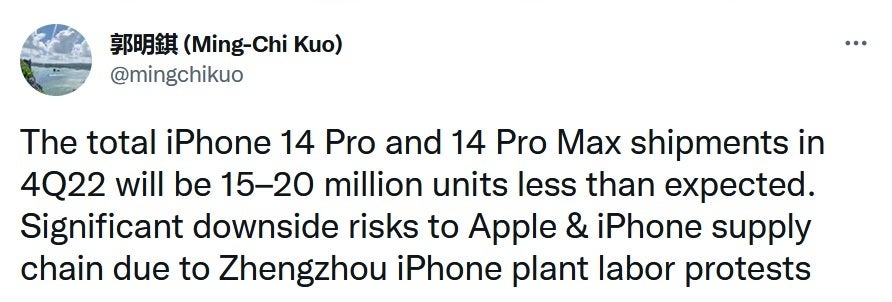

Ming Chi-Kuo expects a huge shortfall of iPhone 14 Pro series models this quarter

As a result, workers were forced to stay on Foxconn's Zhengzhou campus and eat meals in their dorm. Soon, the company realized it had a shortage of workers to man the iPhone 14 Pro series assembly lines right before the holiday shopping season was set to begin. Eventually, a promise to pay new workers bonuses to stay 30 days and 60 days helped Foxconn attract more workers.

Reliable analyst Ming-Chi Kuo sees Apple taking a big production hit this quarter

But last week violence broke out at the facility when workers accused Foxconn of doing a "bait and switch" with their contracts and this resulted in 20,000 workers getting paid off by Foxconn to quit and leave the factory. This was done to stop the clashes between workers and security guards at the plant. Now, according to Medium, TF International's reliable Apple analyst Ming-Chi Kuo has released his estimate of how much Apple will be impacted by the problems Foxconn has experienced at its largest iPhone assembly plant.

Kuo posted a tweet in which he says to expect Apple to ship 15 million to 20 million fewer iPhone 14 Pro and iPhone 14 Pro Max units than expected. That would result in shipments this quarter of 70 million-75 million units of the two pricier 2022 iPhone models, 20% less than the 80 million-85 million units expected by Wall Street analysts.

The reason for the shortfall is easy to explain as Kuo states that the capacity utilization rate of the Zhengzhou iPhone plant was roughly 20% in November. Next month he sees that rate rising to 30%–40%. The analyst says that two of Apple's other contract manufacturers, Pegatron and Luxshare ICT, have been given the task of assembling 10% of the iPhone 14 Pro and iPhone 14 Pro Max orders that Foxconn would normally have produced, but those units won't be shipped until late December.

Kuo says consumers who can't find the iPhone 14 Pro model they want won't defer their purchase to a later time

But Kuo has a bone-chilling forecast that might worry Apple executives including CEO Tim Cook. Kuo says that he sees demand for the iPhone 14 Pro series disappearing! While we are in the midst of an economic recession (according to Kuo), consumers unable to buy an iPhone 14 Pro series model because of the production shortages are more apt to simply forget about making the purchase altogether rather than putting it off until a future date.

Whether these consumers will turn to the cheaper iPhone 14 Plus, or give Android a try (via the Pixel 7 Pro or the Galaxy S22 Ultra) isn't part of Kuo's forecast. But it is something that might keep Cook up at night.

Kuo also notes that iPhone 14 Pro series component suppliers have not been told to cut back on production. As a result, the analyst sees quarter-over-quarter and half-over-half declines in component shipments to Apple for the calendar first quarter and calendar first half of 2023. But Apple might be able to make lemonade out of this mess yet. Kuo says that Foxconn's role as the exclusive supplier of iPhone 15 Pro and iPhone 15 Ultra models to Apple is in jeopardy.

That is actually good news for Apple if it can quickly find a replacement that can assemble such a large number of handsets. The company has been looking to diversify its iPhone production out of China to reduce the risk of production shortages. The problem is finding a facility with enough low-cost experienced workers who can do the job and is served by an able supply chain that can build components in the quantity and quality that Apple needs.

Possibilities include expanding current iPhone production in India or moving production to Mexico or Vietnam.

Things that are NOT allowed: