The iPhone X costs way more to make than the iPhone 8, because of... Samsung

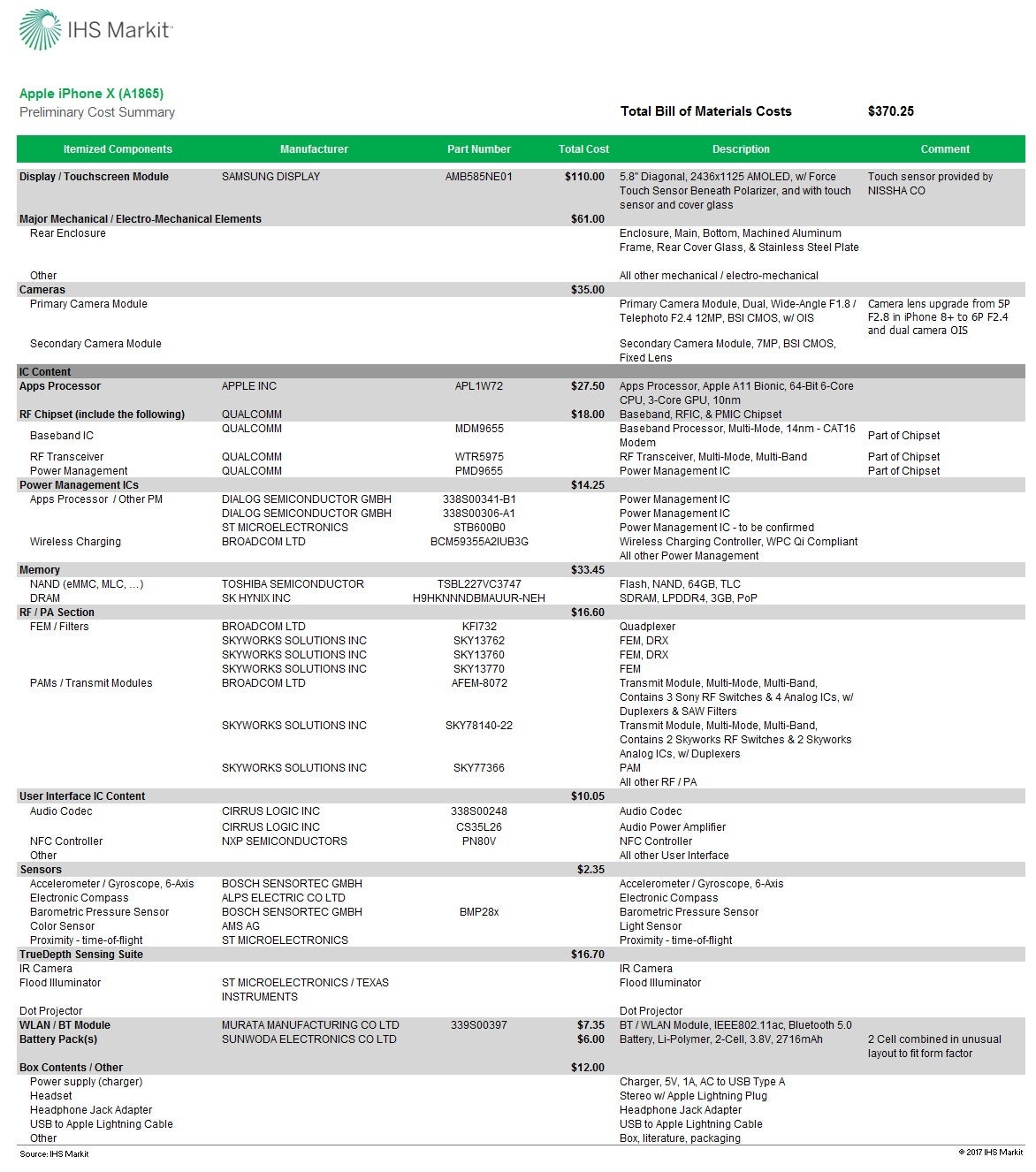

Yesterday, a teardown analysis revealed the iPhone X parts to come at a $357.50 total for Apple when buying in bulk, and today the granddaddy of all industry bill of materials (BoM) research, IHS Markit, came up with a very similar number, $370.25, including the box contents, and costs of assembly.

The difference this time, though, is that IHS included a breakdown of the price for all parts, so now we know why the iPhone X costs $115 more to make than the iPhone 8, which went a similar BoM estimate treatment by IHS last month.

Just as reported yesterday, the most expensive part in the newest iPhone is Samsung's 5.8" flexible AMOLED panel and its accompanying paraphernalia like the Force Touch sensor, polarizer and cover glass. The package amounts up to the whopping $110 for the privilege to turn blueish at an angle. We kid, but about $70 of this tag goes directly to Samsung, which might explain a part of its record-breaking profit announcement.

Surprisingly enough, though, the next most expensive part that goes into an iPhone X production is not the dual camera set, the battery pack, the memory, or the blazing fast Bionic chipset, but rather the rear enclosure. The reinforced glass and the new stainless steel frame cost much more than the aluminum alloy unibody that Apple used so far in previous iPhone iterations, to the tune of $61 to assemble and polish in two colors. Well, the X might cost more to assemble than the iPhone 8, but Apple also asks more for it, so the hefty margin from the "all-screen" handset might lead to a record-breaking quarter for Apple in its turn.

Follow us on Google News

Things that are NOT allowed:

To help keep our community safe and free from spam, we apply temporary limits to newly created accounts: